- #SINGLE PLATE CLUTCH ADVANTAGES INSTALL#

- #SINGLE PLATE CLUTCH ADVANTAGES DRIVER#

There are few other hilly sections of other tracks in GT6 as well.

#SINGLE PLATE CLUTCH ADVANTAGES INSTALL#

Would one be better served to install twin-plate clutches in their cars when racing/driving Matterhorn, for instance? Heck, even Spa has a long uphill (Kemmel Straight). Now, I'm guessing we should assume that the improved engine response and improved acceleration will be slightly greater with the triple-clutch, hence it's price being double that of the twin-plate clutch, 7,000cr vs 3,500cr, respectively. The twin-plate lists no negatives, the triple-plate lists a fairly significant negative. The twin-plate clutch says it " improves engine response, allowing for quicker gear changes and acceleration is improved." whereas the triple-plate clutch says " engine response will improve, as will acceleration, but loss of revs and speed on uphill section will become more pronounced."

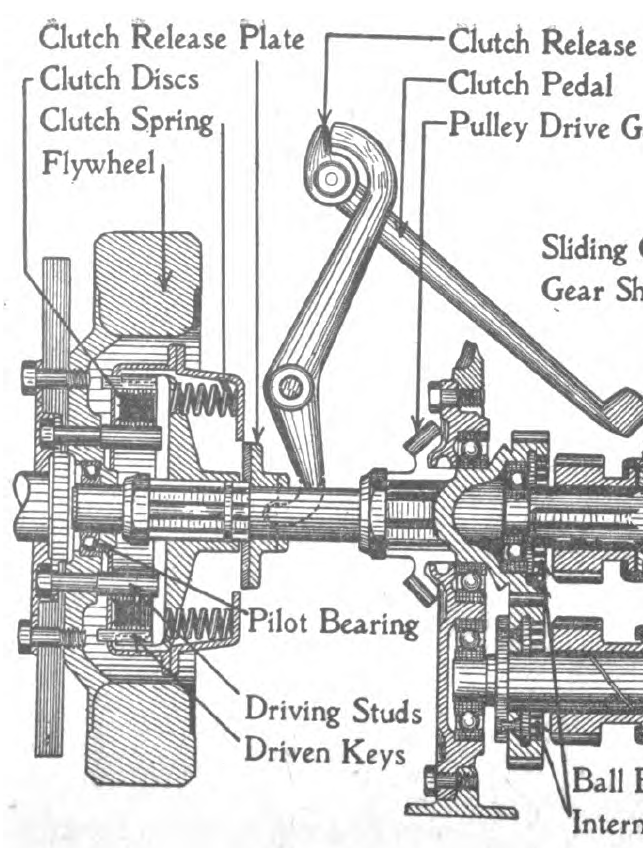

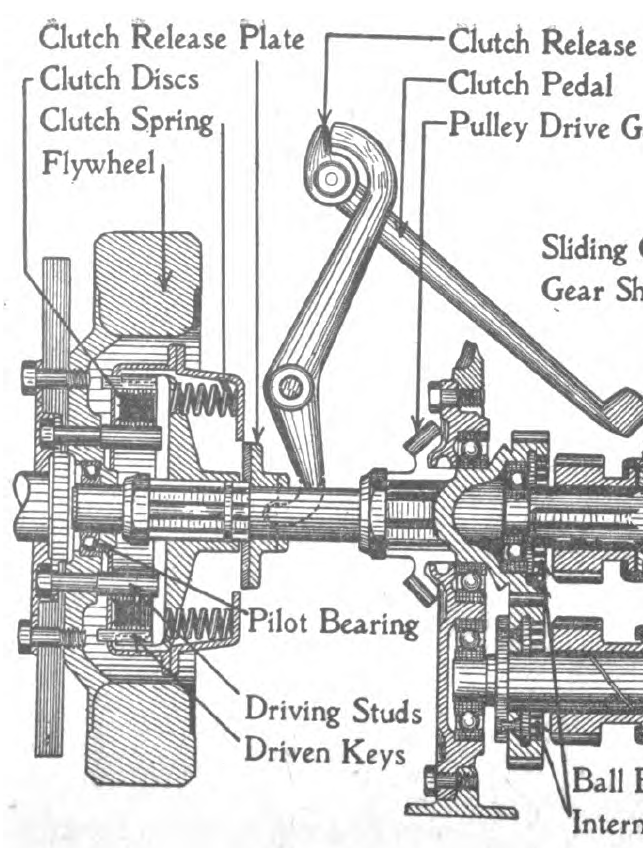

Medium duty vehicles, such as Jeeps, Cars etc.Ok. Trucks, Buses, etc., where space availability is not a problem. Large effort (or force) is required to be applied on clutch plate as compared to multi-plate clutch. Therefore, single plate clutch cannot be used in the applications, where space availability is a problem. Due to this, overall size of single plate clutch gets increased. Use of single plate clutch is not preferred, if large magnitude of power is to be transmitted, because surface area of clutch plate has to be increased considerably for high power transmission. Better availability to damp out torsional vibrations. Shifting of gear is easy, if single plate clutch is used. Better heat dissipation (heat is generated due to friction between contacting surfaces). Therefore, drive gets disengaged and power is not transmitted to clutch plate and hence, clutch shaft Advantages of Single Plate Clutch This loosens the contact between clutch plate and flywheel. When the clutch pedal is pressed down, release lever pulls the pressure plate away from clutch plate against the axial force offered by clutch springs and thereby, compressing clutch springs. This condition is referred as Clutch Pedal Position – Pressed – Down. Further, the power is transmitted from clutch plate to clutch shaft through mechanical splines.įor disengaging the clutch, the clutch pedal is pressed by the driver. Therefore, drive is engaged and power is transmitted from the flywheel to the clutch plate due to friction existing between their contacting surfaces. towards flywheel) with clutch plate being sandwiched between pressure plate and flywheel. When the pedal position is up, the axial force offered by clutch springs is pressed against the flywheel (i.e. This condition is referred as Clutch Pedal Position-Up. It means that, clutch pedal is not pressed by the driver.

1 shows single plate clutch assembly in engaged position. To understand the working of single plate clutch, let us consider following two cases:įig. Thrust bearing takes care of the axial load, which comes during sudden release of clutch springs, when they are compressed in axial length due to axial force applied by release lever at the time of disengagement of clutch. Clutch shaft is splined near the central hub, where the clutch plate can slide.

#SINGLE PLATE CLUTCH ADVANTAGES DRIVER#

Release lever is used to transmit the motion of clutch pedal to pressure plate, when clutch pedal is pressed by driver to disengage the clutch.Ĭlutch shaft is connected to input shaft of gearbox. Clutch springs are used to keep the clutch in engaged position, when pedal position is up. In case of single plate clutch, six to eight clutch springs are radially mounted in between one clutch plate and pressure plate. One side of pressure plate has flat surface, which engages with the clutch plate.

0 kommentar(er)

0 kommentar(er)